SACHEM’s innovative core-shell cathode coating technology uses a lower temperature method to prepare metal oxide shells on active ceramic particles for lithium ion battery cathode materials. This technology is designed to be used on a variety of ceramic particles and has the ability to uniformly coat particles while controlling shell thickness.

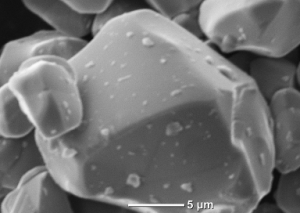

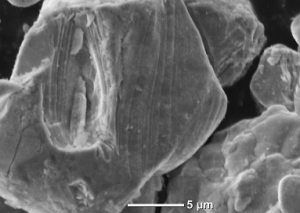

Active ceramic particle morphology after treated by SACHEM core-shell chemistry

Core-Shell Cathode Coating Process Advantages

- Room temperature process for precursor shell formation

- Homogeneous and continuous shell

- Precursor shell calcination temperature 180 – 400°C

- Controllable shell thickness

- Applicable for various metal oxide shells and nonmetal oxide shells

Core-Shell Cathode Coating Performance Benefits

Inefficiencies in cathode materials is the main reason lithium ion batteries have not progressed faster and opened the technology up to more applications. Today’s materials have low capacity, capacity fade upon operation time, and a drastic rate capacity drop at higher current discharge. Some cathode materials also have insufficient thermal stability and poor overcharge performance. This is caused by a breakdown in the solid electrolyte interface (SEI) layer, leading to poor cycling life and capacity loss. SACHEM’s core-shell technology provides structural and thermal stability which leads to the following benefits:

- Elevated operation voltage

- Improved rate capability

- Suppressed capacity fade

- Enhanced discharge capacity

To see data findings from this technology, download our White Paper titled, “SACHEM’s Core-Shell Chemistry for Li Ion Battery Application.”

![]()